Some client may need inline flexo print and independent flexo print machine, when the order of paper bag is big amount and the picture is not change frequently, we will recommend inline print, 2 and 4 color is more suitable. If client’s paper bag order is small and Customized picture with various type or registed with more than 4 color, we will of course to suggest client purchase independent flexo print machine, and one important advantage of independent model is the material loading width can be wider with 1500mm diameter jumbo roll. In this article, we would like to show you how to operate the print unit. Because whatever you use the inline print or independent printing machine, the operate instruction is almost same.

There are 2 sets press rubber cylinder as the picture shows, when you through the kraft paper at print unit, should drag the press rubber cylinder.

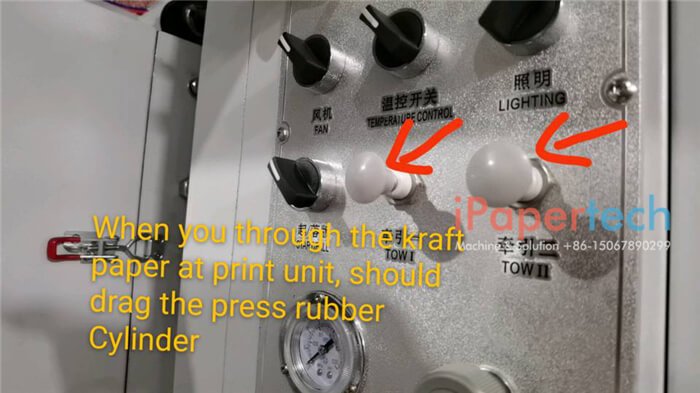

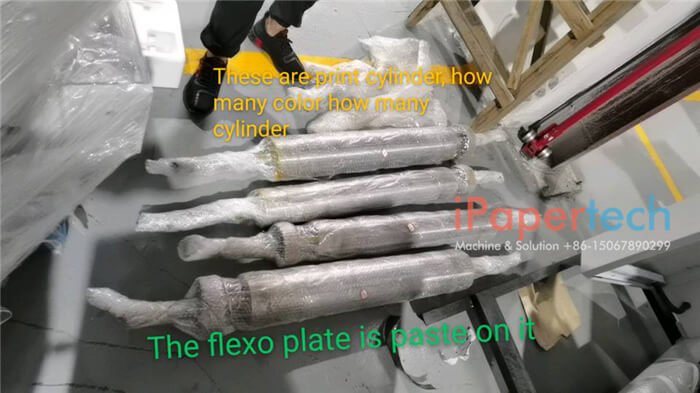

When you change the print cylinder, need open the cylinder shaft holder, no worry about if it is acceptable for big and heavey cylinder, Because we even Customized 2000mm width print machine for client, we use the same design. And when change the print cylinder, do not forget to put off the ring on the cylinder shaft.

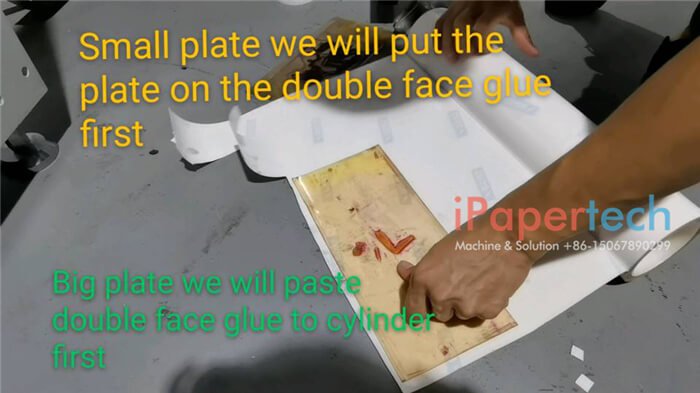

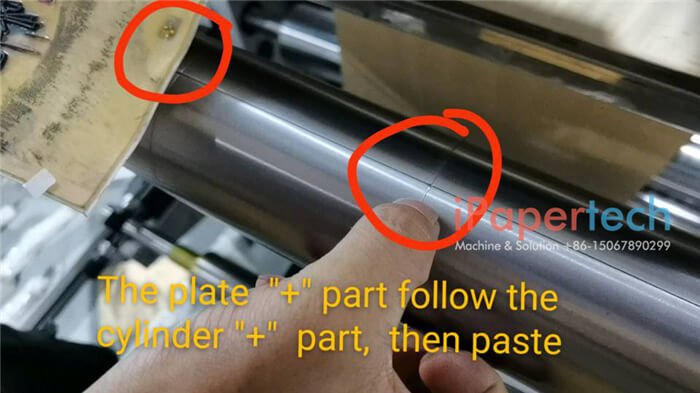

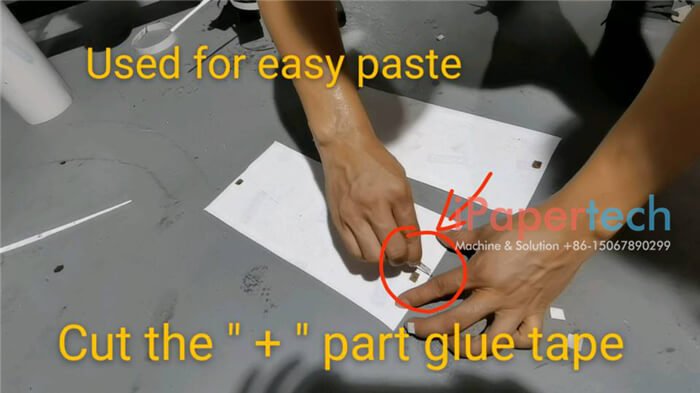

When you mounting the flexo plate, if the plate is small we will prefer to paste the plate on that glue tape first, if the plate is big, we will paste the double face glue tape on the print cylinder first. And do not forget to cut the “+” part glue tape to easy paste while follow the “+” on the cylinder. And we need paste normal glue tape to protect the flexo plate two side.

When you operate the register, we will rotary the front and back wheel to move it left and right, also press the black button to control the cylinder up and down.

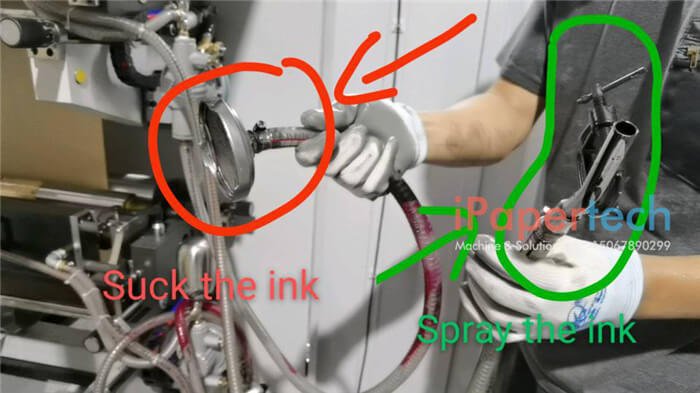

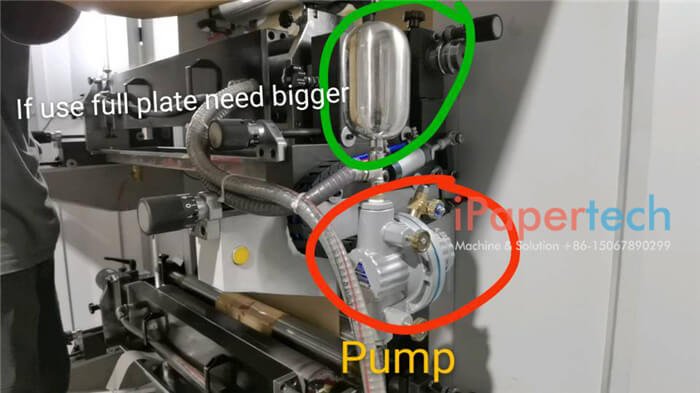

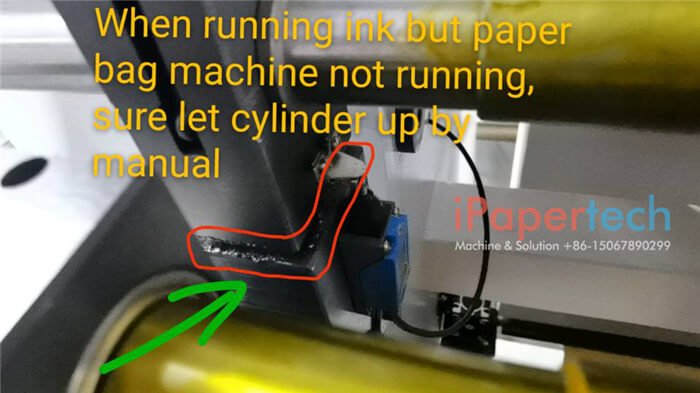

When you running the ink on the print machine, but paper bag machine not running, let the cylinder lift up by manual, then the ceramic anilox will not touch the cylinder, it called empty running the ink, not let the ink drying.

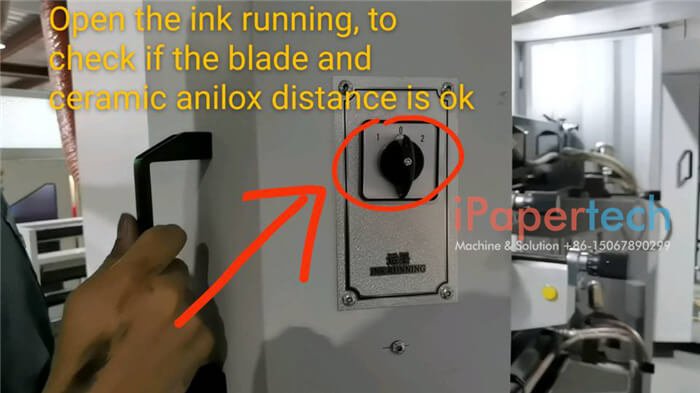

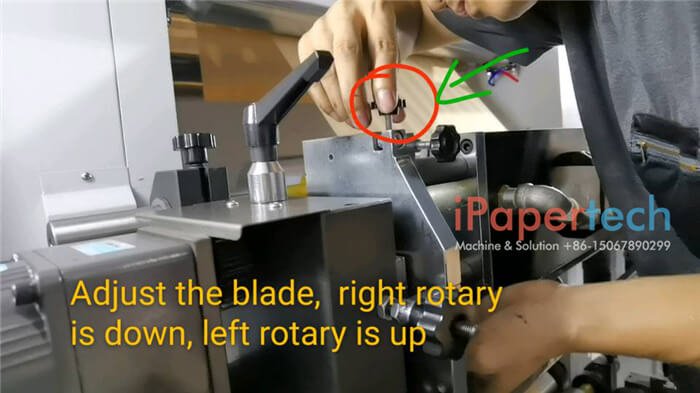

When you running the ink, check the distance of ceramic anilox and chambered doctor blade, confirm the sponge gasket is touch the ceramic anilox, and we also need adjust the blade position, right rotary is down, left rotary is up. Before running the print unit, do not forget to clean the chambered doctor blade and brush the oil on the main movable part.

WIN WIN COOPERATE TOGETHER!