As we know, if we not use the adjustable forming plate, we will use the movable forming plate, and when we use the movable forming plate, each size bag has its own independent forming plate, we may change it frequently based on various client requirements and market demands. Normally we change one size forming plate need half-hour, not include the forming plate position operation time. But it is easy to confirm the plate position on the paper bag machine. In this article, we only show you how to put off the forming plate and replace the suitable width plate on the plate holder.

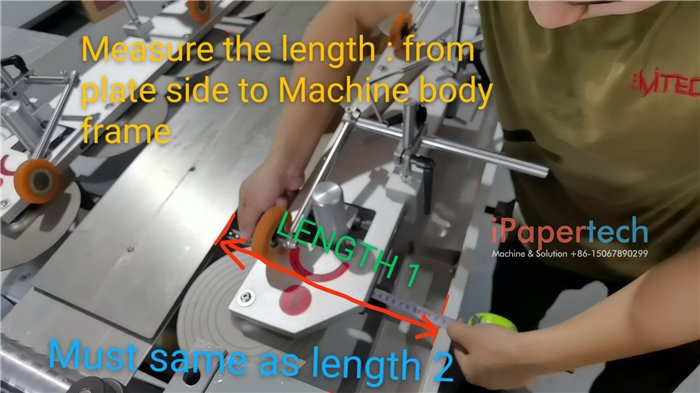

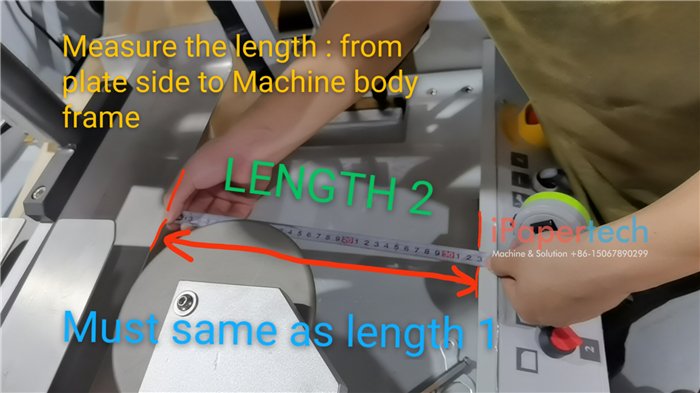

Normally, the original machine with 3sets plate holder and 3sets bag forming plate. The step type plate holder is used for a 2-5cm gusset, the highest plate holder is used for 5-12cm gusset to forming the big side width paper bag. The short plate holder is used without a gusset bag forming. While you fixed the plate holder on the bag forming device, we need to adjust the whole device from the front and back side. At first, we need to measure the length from the plate side to the machine body frame, we call it “LENGTH 2” and “LENGTH 1”, these two lengths must same to ensure the device keeps in the same level.

Please noted that the circle disc should between the two forming plates, and should be loose can not be compact. Because the disc just used for bag better gusset step by step, not you fix the gusset shape, so it should be movable.

And we can control the whole gusset device by rotary that while which along with the machine right side. We can also make the plate up and down by rotary thr handle wheel. Left is up, Right is down.

Thanks for through our article with patience, we will keep writing a similar article in after-sales and installation for further installation and training guide.