Brand new ZB1260S-450 Fully automatic sheet feeding environmental paper shopping bag making machine (independent innovation) adopts international advanced production process and management system. This machine equips advanced compact servo handle cut-off system to replace the traditional complex mechanical structure, which reduced the setup time and supplied a comfortable operation space.

The bag making machine and handle making unit have separate servo control systems to avoid the handle waste. Intelligent switch between twisted rope handle and flat handle provide a wider range of business scope for customers.

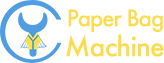

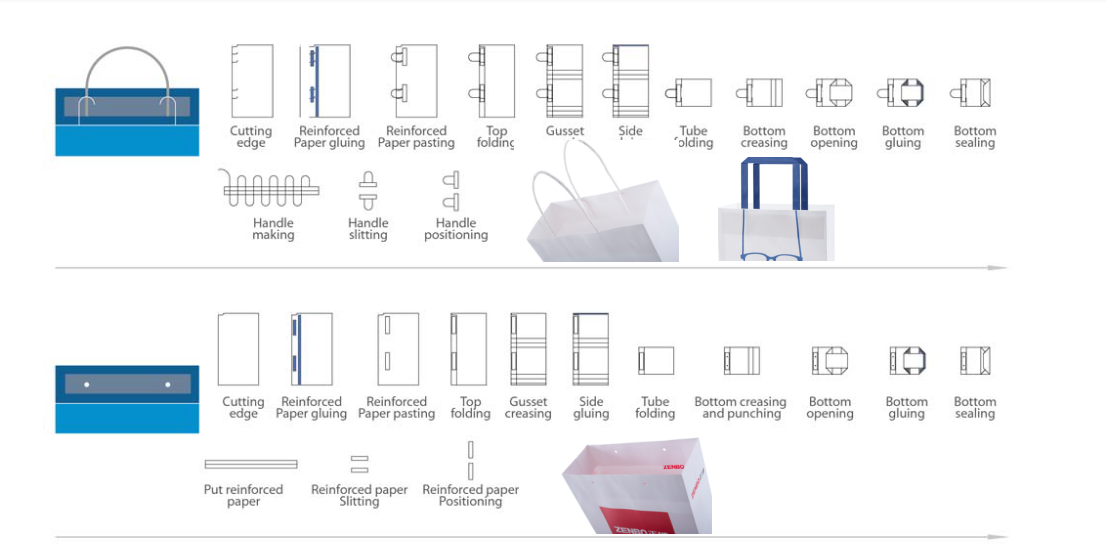

ZB1260S-450 is a fully automatic paper bag making machine which can in-line produce twisted rope handle. This machine can produce 3 types paper bag, 3 different crafts as below.

Details of Paper Bag Machine

| This machine can produce 3 kinds of different paper bags |

|

|

|

| Max.sheet(LXW) | 1200*600mm | 1200*600mm | 1200*600mm |

| Min.sheet(LXW) | 620*320mm | 620*320mm | 620*320mm |

| Sheet Weight | 120g-190gsm | 120g-190gsm | 120g-190gsm |

| Bag Width | 220-450mm | 220-450mm | 220-450mm |

| Bottom Width | 70-170mm | 70-170mm | 70-170mm |

| Bag length | 235-490mm | 235-540mm | 235-490mm |

| Top folding width | 40-60mm | / | 40-60mm |

| Handle patch length | 189mm | 189mm | 189mm |

| Handle patch width | 30-50mm | 30-50mm | 30-50mm |

| Handle patch weight | 140gsm-200gsm | 140gsm-200gsm | 140gsm-250gsm |

| Handle patch roll diameter | φ 1000mm | φ 1000mm | φ 1000mm |

| Handle patch roll width | 60-100mm | 60-100mm | 60-100mm |

| Paper rope diameter | 4-6mm | 4-6mm | / |

| Handle rope height | 170-190mm | 170-190mm | / |

| Speed | 40-70 pcs/min | 40-70 pcs/min | 40-70 pcs/min |

| Total power | 40 KW | 40 KW | 40 KW |

| Total weight | 24.5 T | 24.5 T | 24.5 T |

| Glue type | Water base glue/hot melt glue | Water base glue/hot melt glue | Water base glue/hot melt glue |

| Machine size (L* W * H) | 16450*5300*3100mm | 16450*5300*3100mm | 16450*5300*3100mm |

| Finished bag picture |  |

|

|