Many factories may focus on machines, focus on design, but the package of machine packaging also not ignore, it is very important in the deal of paper bag machines. Because the paper bag machine, Whatever V Bottom or Square Bottom, they are both not small investment, we can understand when the client pays a lot of money but receive a broken machine, how disappointed client will feel.

So we develop a professional packaging team at our own factory, every day they do the package, and follow the standard Process strictly.

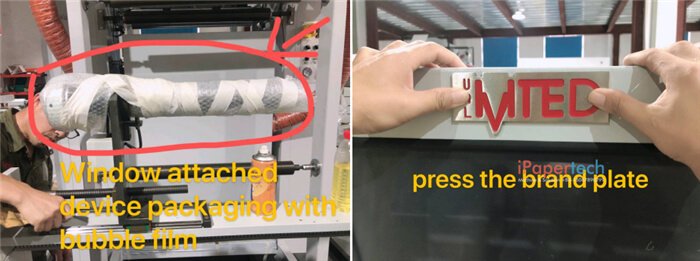

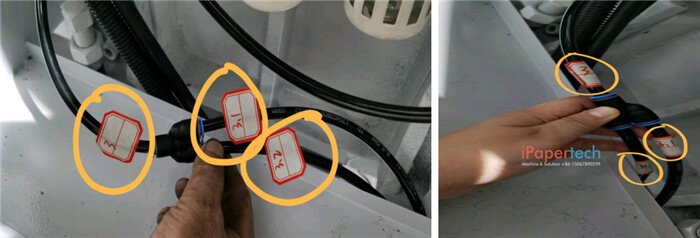

There are many cables and air tubes on the machine, and before machine shipping, we should separate then and hide them in the machine body. And we also need Mark or name it by the label. For example, we need to hide the sponge gasket in the print Machine, hide the air tube and wATER based glue tube in the bag machine.

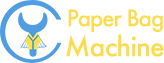

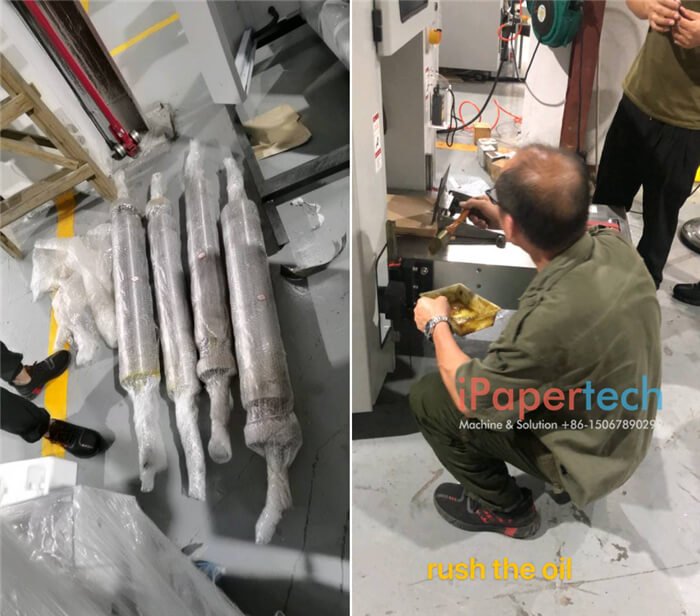

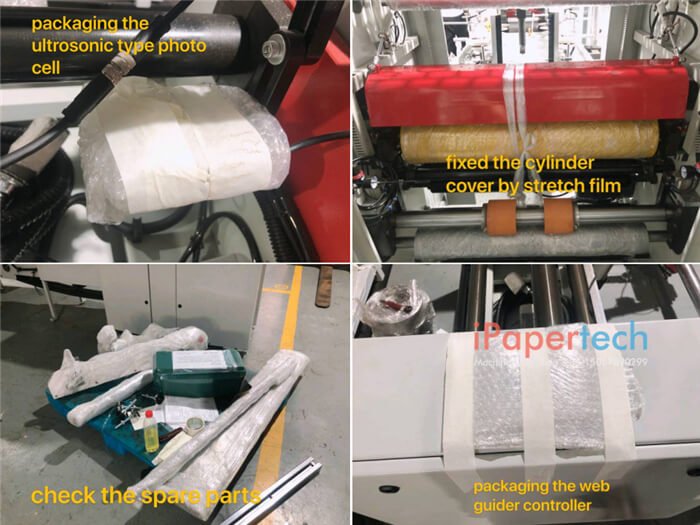

And we need to brush some oil to protect the machine metal part, use the air gun to clean the dust on the machine gear part, use the stainless line to fix the print cylinder on the print unit. Then we will double-check the spare part list. At final, we will paste our brand logo on the machine. Then our packaging team leader will sign it with a clear date and send it to our sales department.

During the packing work, we use three-layer film to finish the packing, they are bubble film, PE film, and stretch film, at final we will pack it with export wooden package, and fix then in the 40HQ container. You can see our main electric parts are protected well by our package, like PIC touch screen, web guider, ultrasonic type cell, photo cell and manual book…

WIN-WIN COOPERATE TOGETHER!