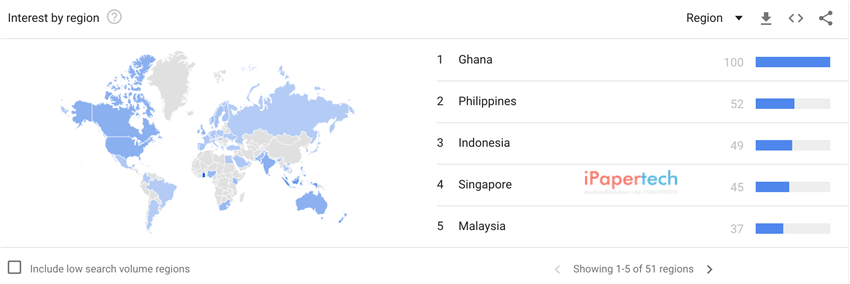

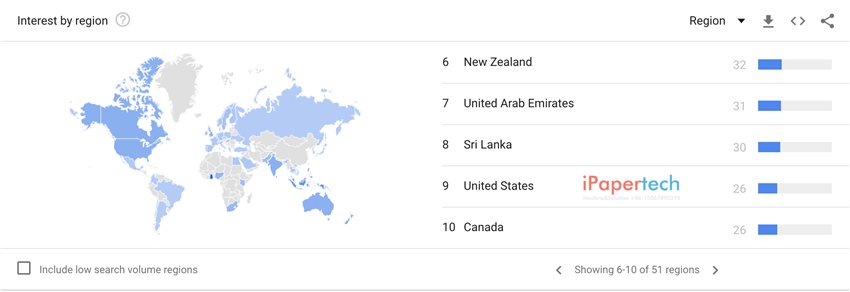

Along with the implementation of “plastic bans” in the world, more and more countries began to replace plastic bags with paper bags, the whole demand was soaring. The following is google about paper bag machine search hotness. The top 10 countries are Philippines, Singapore, Malaysia, Ghana, Indonesia, New Zealand, Sri Lanka, United Arab Emirates, Canada, United States.

Paper Bag Roaring Demand

Paper Bag Roaring Demand

When facing the strong demand, many of our customers are also new to the industry, ready to make a big impact in the paper bag machine industry. In this article, we will introduce the equipment and related information about the paper bag machine factory needs.

1.Paper Bag Machine Equipment

Before buying the paper bag machine equipment, you need to do sufficient market research in the market to determine the bags you want to produce, and then purchase the corresponding appropriate paper bag machine equipment.

Now the main circulation of kraft paper bags on the market are mainly gift bags, food packaging bags, shopping bags, grocery bags, dried fruit bags and so on.

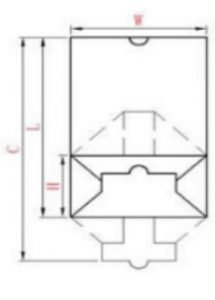

And our factory equipment can support to do the machine for following styles.

Paper Bag Types

Paper Bag Types

The material is kraft paper, and the paper thickness is between 60-150gsm. The A,B,C,D paragraph corresponds to the sharp/flat bottom paper bag machine, mainly used to pack food. E,F,G,H paragraph corresponds to the square bottom paper bag machine, mainly used to do supermarket grocery bags, shopping bags and so on.

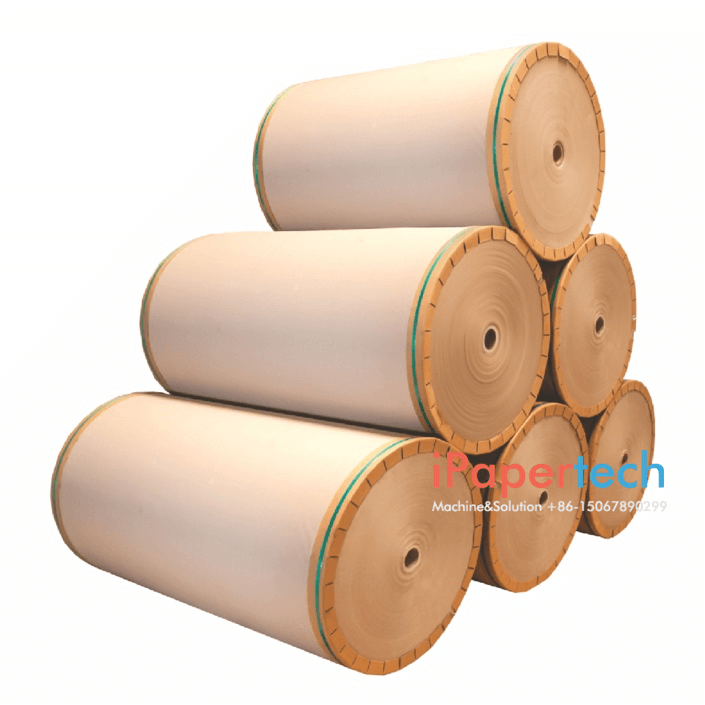

Raw Material of Paper Bags

Raw Material of Paper Bags

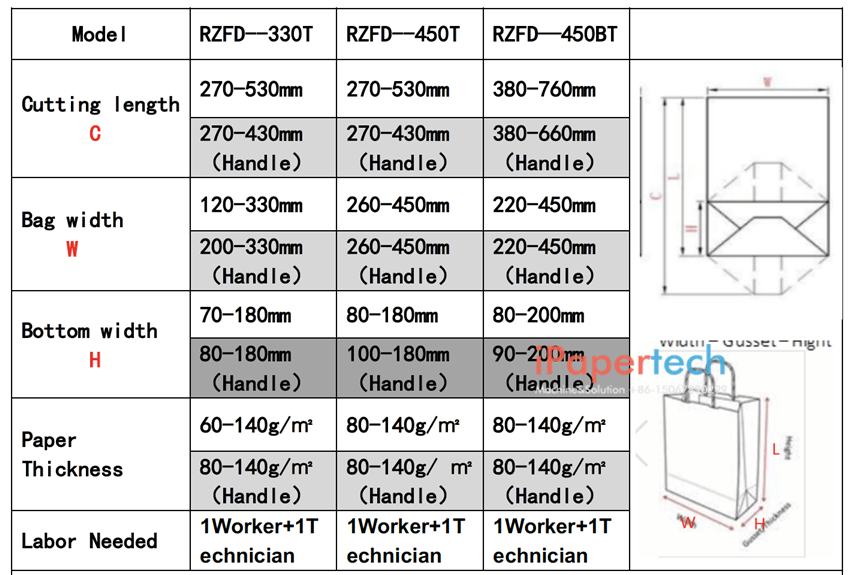

After determining the basic bag making style, we need to match the right model according to the size of the bags. The following are our factory models for selection, and we also support customized models, please contact us for confirmation of specific needs.

A, Sharp/Flat Bottom Paper Bag Machine—For Sharp Bottom Bag

Budget Range:52000USD-925000USD

Sharp Bottom Paper Bag Machine

Sharp Bottom Paper Bag Machine

We have below Models.

a, Model NO.: JD250

Bag width: 70-250mm, gusset: 20-120mm, bag cutting length: 100-450mm, adopt Japanese Yaskawa servo motor and british PLC

Machine Size: 6800x2300x1900mm

Operator needed: 1

b, Model NO.: JD350

Bag width: 70-350mm, gusset: 20-120mm, bag cutting length: 175-715mm, adopt Original Germany LENZE Servo motor

Machine Size: 8800x2300x1900mm

Operator needed: 1

B, Square Bottom Paper Bag Machine—For Grocery Bag

Budget Range:52000USD-925000USD

Adopt Germany Original rexroth servo motor and PLC

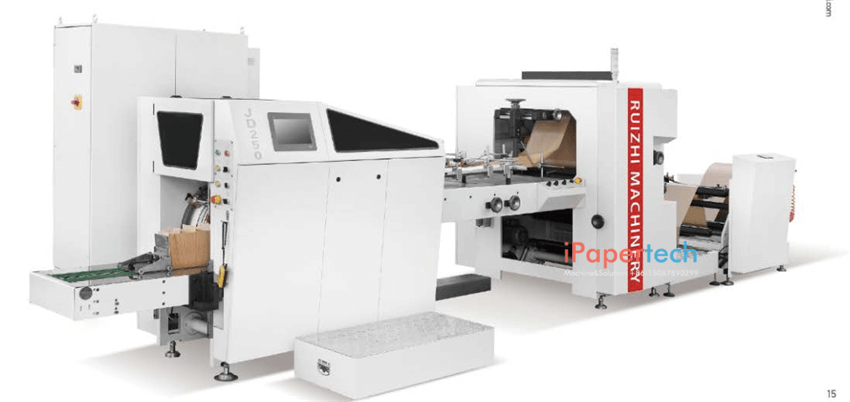

Square Bottom Paper Bag Machine

Square Bottom Paper Bag Machine

We have below Models.

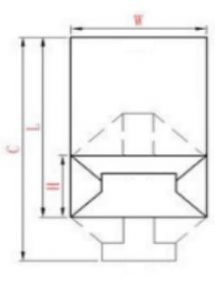

| Model | RZFD-190 | RZFD-330 | RZFD-450 | RZFD-450B |

| Cutting length – C | 190-370mm | 270-530mm | 270-530mm | 380-760mm |

| Paper bag width – W | 80-190mm | 120-330mm | 260-450mm | 240-450mm |

| Paper bag bottom width – H | 50-105mm | 60-180mm | 80-180mm | 80-200mm |

| Paper thickness | 50-130g/m2 | 60-150g/m2 | 70-150g/m2 | 80-150g/m2 |

| Paper bag speed | 30-200 pcs/min | 30-180 pcs/min | 30-150 pcs/min | 30-140 pcs/min |

| Paper roll width | 280-640mm | 380-1040mm | 700-1280mm | 700-1330mm |

| Roll paper diameter | 1200mm | 1200mm | 1200mm | 1200mm |

| Machine power | 3phase 4line 380V 12kw | 3phase 4line 380V 15kw | 3phase 4line 380V 18kw | 3phase 4line 380V 20kw |

| Machine weight | 5800 kg | 7200 kg | 7500 kg | 7800 kg |

| Machine size(mm) | 8200x3200x1900 | 9200x3700x2000 | 9200x3700x2000 | 9200x3700x2000 |

| Bottom types |    |

|||

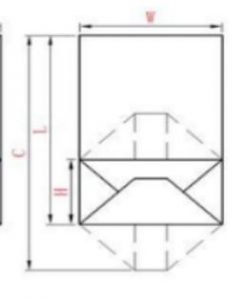

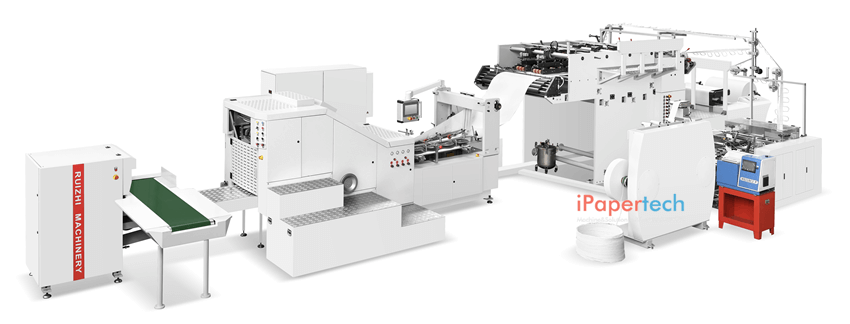

C, Carry Bag Making Machine—For Carry Bag With Handle

Budget Range:130000USD-345000USD

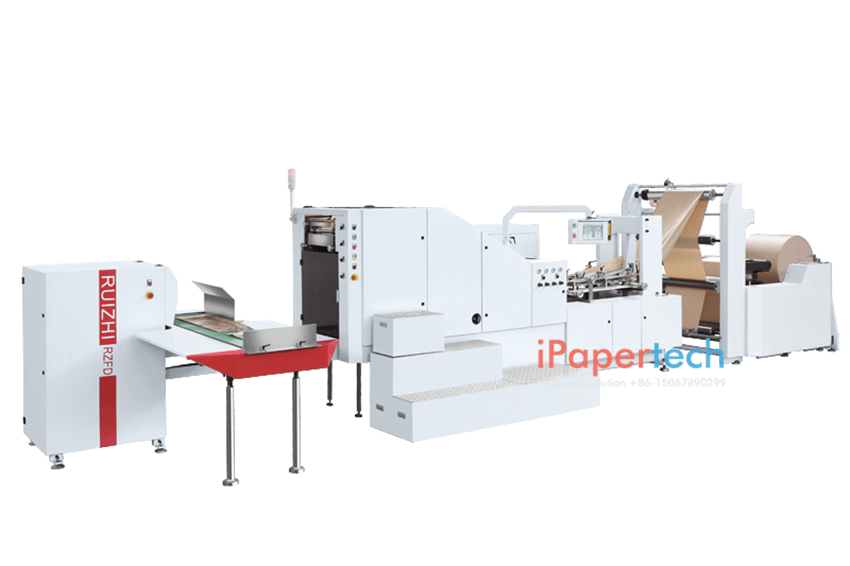

Fully Automatically Carry Paper Bag Machine

Fully Automatically Carry Paper Bag Machine

As for paper bag with handle machines, we have semi-automatic and fully automatic machines to choose from. Semi-automatic machine is to produce paper bag by normal square bottom paper bag machine, and then stick the round or flat wrist on it manually. Automatic machine is to achieve the wrist production and paste, bag production, the final product is carry bag.

Our round rope automatic paper bag machine has the following models.

Machine Video:

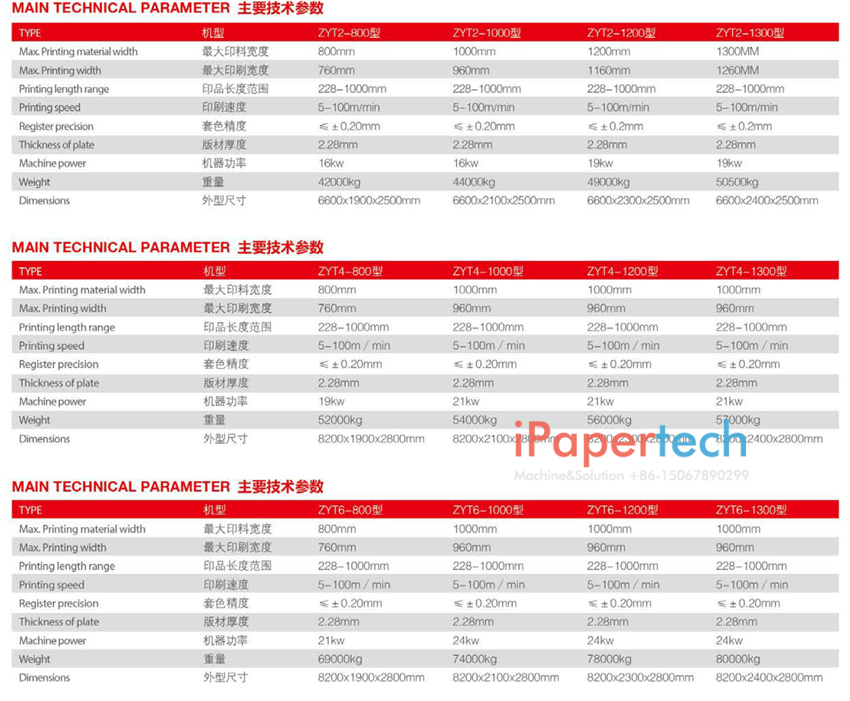

2. Paper Printing Equipment

a, Standard Offline Printing Machine Budget Range:28000USD-46000USD

b, Standard Inline Printing Machine Budget: Range:18000USD-41000USD

We have the professional flexo printing machine with ceramic anilox, doctor chambered blade, auto recycling ink pump. Have the 2 colors/4 colors and inline and offline are optional.

Flexo Printing Bags

Flexo Printing Bags

Q: Many buyers will ask, Whether to choose the inline or offline printer machine?

A: Generally speaking, for new paper bag manufacturers, it is recommended to purchase a split printer, as one split printer can meet the needs of two paper bag machines, as there are many printing templates for small orders. In the case of large orders, it is recommended to use a one-piece printing machine to increase efficiency and reduce material waste.

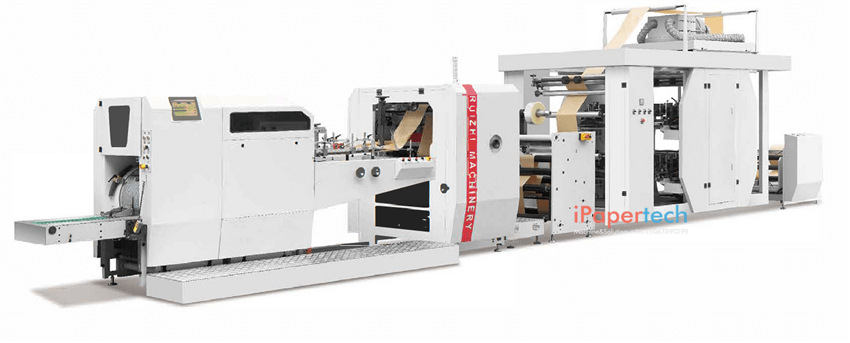

Paper Bag Making Machine With Inline Printer

Paper Bag Making Machine With Inline Printer

We have below models.

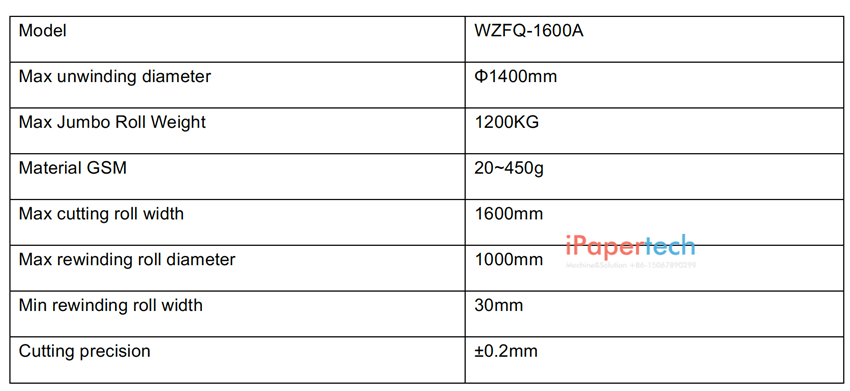

3. Slitting machine

Budget Range:30000USD-35000USD

The slitter is used to slit large rolls of paper and can be set to different slitting widths depending on the size of the paper bag.

Paper Slitting Rewinder Machine

Paper Slitting Rewinder Machine

Labor required:1 person

Machine Video :

The above is the basic equipment that a paper bag factory needs to have for reference only. Depending on the size of the paper bag, the corresponding press machine and slitting specifications may be different. We also support partial customization needs, if interested, please contact us.