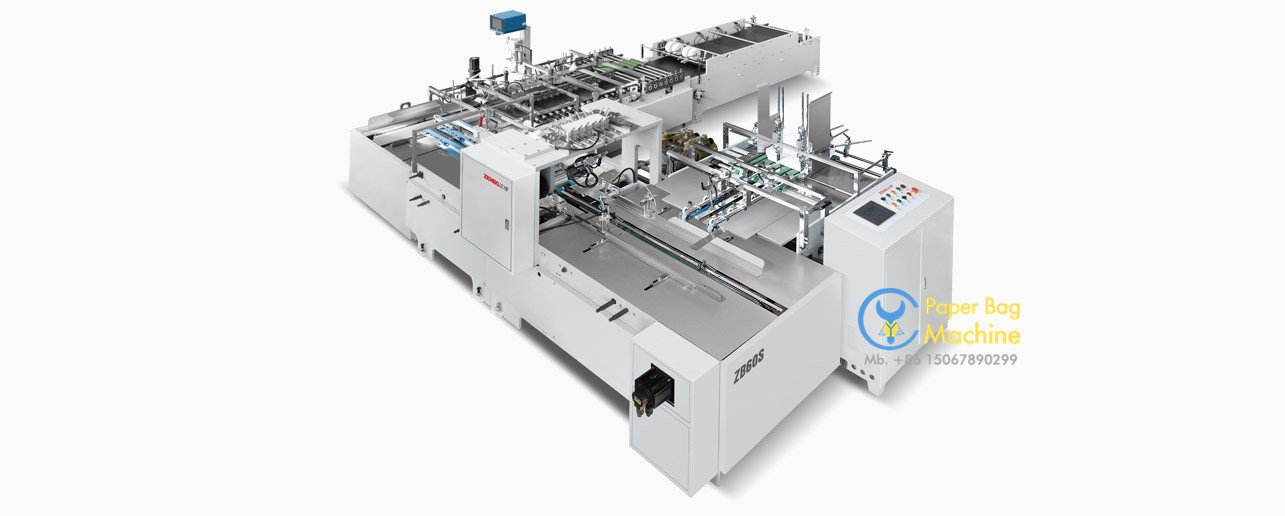

ZB60S Handbag bottom gluing machine(independent innovation), adopts Servo motor drive, PLC control system, achieve automatic bottom cardboard inserting function. It meets the special requirement of Boutique paper bag making.

The basic working flow of this machine is Automatic feeding the unclosed-bottom paper bag, bottom opening, bottom cardboard inserting, two times positioning, coated water base glue, bottom closing and compaction output the paper bags.

With Servo system ensure the bottom cardboard process is stable and high precisely.

Use gluing wheel to coated the water-base glue on bag bottom make the glue is evenly coated on full bottom, not only improve the bag quality but also increase the profit for customers.

Details of Paper Bag Machine

| Paper Weight | 140 – 250gsm |

| Bag Width | 180 – 410mm |

| Bag Height | 250 – 500mm |

| Bottom Width | 80 – 175mm |

| Bottom Cardboard Width | 70 – 165mm |

| Bottom Cardboard Length | 170 – 400mm |

| Bottom Cardboard Weight | 250 – 400gsm |

| Machine Speed | 50 – 80bags/minute |

| Total Electrical Power | 8KW |

| Glue Types | Water Base Glue |

| Machine Dimensions (L * W * H) | 5100 * 6600 * 1733mm |