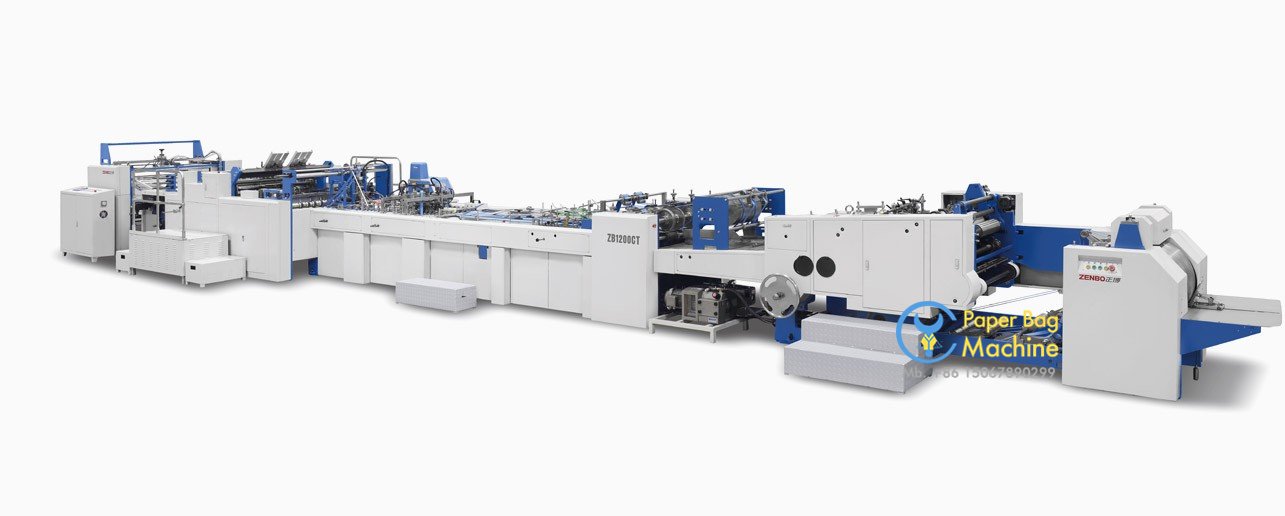

ZB1200CT-430 possess a large number of independent patents, create the high-speed automatic paper bag production. This machine adopts servo system for top reinforced card taking, realize the top reinforced card paste position adjustable. New “half-blade” device ensure bag body trackless. Adopts with PLC and Servo control system, reserve of extensible intelligent port for future system upgrades and remote services.

The basic working flow is sheet feeding, creasing, servo top reinforced card taking and pasting, top folding (insert pasting), tube forming, gusset forming, bottom open and gluing, bottom folding and closing, compaction and output.

Details of Paper Bag Machine

| Max.sheet (L X W): | 1200 * 600mm |

| Min.sheet (L X W): | 540 * 320mm |

| Sheet weight: | 120 – 250gsm |

| Bag height | 220– 500 mm |

| Top folding width | 30 – 60mm |

| Bag Width: | 180 – 430mm |

| Bottom Width(Gusset): | 80 – 170mm |

| Reinforced paper width:: | 25-50 mm |

| Reinforced paper length: | 160-410mm |

| Bottom type | Square bottom |

| Machine speed | 40 – 70 Pcs/min |

| Total power | 35 KW |

| Total weight | 16.5 T |

| Glue type | Water base glue and hot melt glue |

| Machine size (L * W * H) | 21000 * 3250 * 1800 mm |

Standard configuration America Nordson hot melt adhesive system: fast adhesion product, quickly enter the next process.

Standard configuration Bag compaction table: layers compaction bag device, fast adhesion, compaction, overlapping output, convenient collection, improve work efficiency.